If you use your table saw as a work surface, remove the splitters so you do not accidentally hit them and bend or break them.When making partial cuts like this, the remaining portion of the board can run into the splitters causing it to stop feeding. Splitters can get in the way if you are cutting grooves into a board.Splitters are a good option for an old saw that does not have a riving knife or blade guard.These indicate how much "featherboard effect" the splitters can have when keeping the kerf open. Read the splitter instructions to understand the marks on each side of the splitters.The MJ Splitters are available in both thin and regular kerf size to be compatible with different saw blade thicknesses.

AJUST BLADE ON OLD CRAFTSMAN TABLE SAW INSTALL

Think about whether you want to install one or two splitters, considering how much space you have behind the blade and how high you want to raise the blade. The MJ Splitters were easy to install.If you want to tilt your saw blade, you will need to place your original insert plate on the saw.This was an issue with the original insert plate. The insert plate helps with tear out and also keeps thin pieces from getting stuck in the gaps next to the blade.Here is a recap of my thoughts and general notes on the insert plate and splitters: Also, thanks to Peachtree Woodworking Supply for having the insert plate for my old saw in stock.

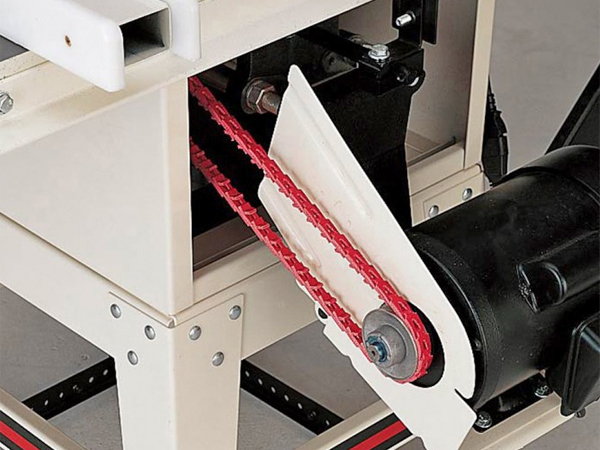

This way you have a way to mount it to your jig tooth cutting jig.įinally, mark the locations for the mounting holes and a spot for the knob to pass through.Thanks to MicroJig for sending me their MJ SteelPro Splitter kit to try out. ***NOTE: If you do this, be sure to do it AFTER cutting out the teeth. (Photo 4) This step is completely optional as it has no effect on the function of the mod. Next I took a hole saw to remove a section from the middle of the gear. It is important to keep it wide enough to allow for a substantial size piece of wood to fit in-between the teeth. My width was about the size of two saw kerfs. I made a jig using my cross cut sled (Photo 2) for this, but again, could be done with a jigsaw or band saw. Rusty old saw blade The brand is so widely recognized that most people refer to any circular saw as a Skilsaw, much as some people refer to photocopiers as a Xerox machine. If I were to do it over, I would target a gear diameter 1" larger then the wheel diameter.***ĭivide the gear into equal sections (I choose 32) and cut out the teeth. ***In retrospect, I probably made the diameter of my gear too large. I cut the circle out using a jig for a table saw (see link) It could easily be done by hand with a jig saw, band saw or giant whole saw (Photo 1). The gear is one of the two major components of the modification. Thereby preventing the wheel from turning during operation and eliminating the need to lock the blade in with the factory installed angle lock. I did this by mounting a toothed gear onto the angle adjustment wheel and an arm that falls in between the teeth of the gear. My solution was to create a way to manually keep the angle adjustment wheel stationary. Or else my hobby would be causing me more stress than pleasure. Second: Whether the factory angle lock is engaged or not, the angle changes while the saw is running due to the inherent vibration of the saw.Īfter much frustration, I decided that something needed to be done about this. So the very act of locking in your desired angle, throws off your angle!!! Crazy! When I engage the angle lock that comes with the saw, it throws off the blade by 1-2 degrees. However, there are two major problems.įirst: I turn the angle adjustment wheel to my desired angle. It has a cast iron table and very robust motor.

I have an older Craftsman table saw that is built like a tank.

AJUST BLADE ON OLD CRAFTSMAN TABLE SAW PROFESSIONAL

Any woodworker (both professional or hobbyist) will tell you that it is critical to have accurate angle cuts.

0 kommentar(er)

0 kommentar(er)